Product Category

We are manufacturer and specialize in producing fried instant noodle production line,non-fried instant noodle making machine...

Recommended Products

Our team could provide processional service, good quality products, delivery in time and competitive price.

Cooperation

Sincerely want to cooperate with customers from all over the world

Turkey HUBAT group 510 fried instant noodle line

Introduce:

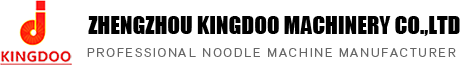

We exported one set model 510 fried instant noodle line to Turkey in 2022 . Machine capacity is 120,000 pieces 8 hours , and one line can produce two types noodle (round and square) . Match Siemens brand motors and gear boxes, NSK bearings.oil system (like oil pot,oil pipe,oil tank,heat exchanger) are made of stainless steel 304 .

Russia model 300 fried instant noodle line

Introduce:

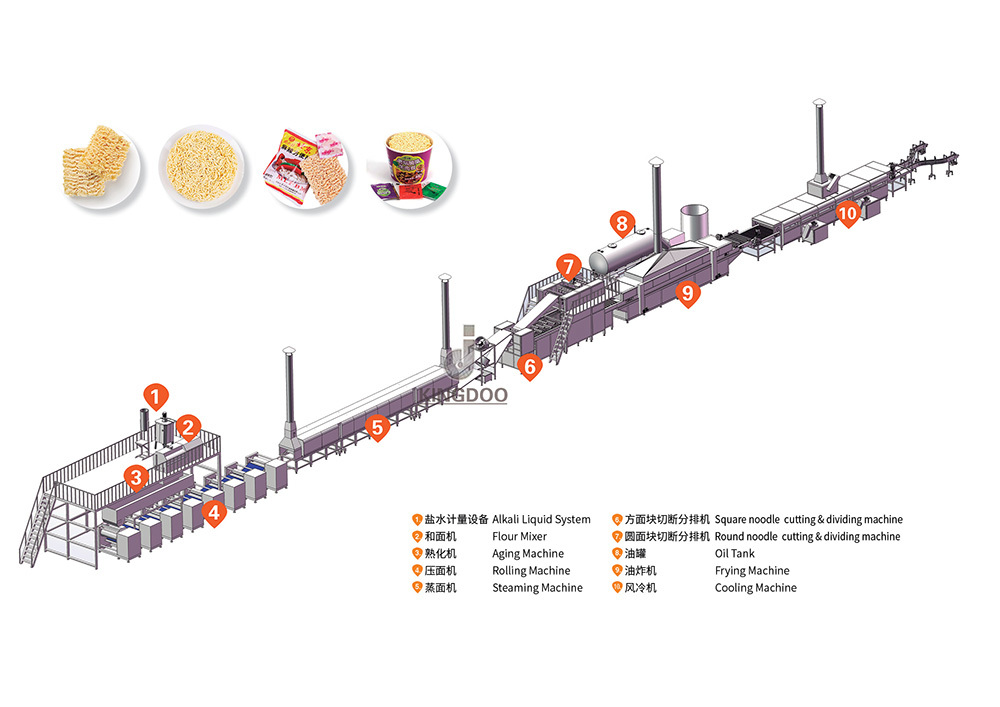

We exported one set model 300 fried instant noodle line to Russia VED EXPERT COMPANY in May 2017 . This noodle line capacity is 60.000 pics for 8h.

Indonesia model 1000 dried noodle line

Introduce:

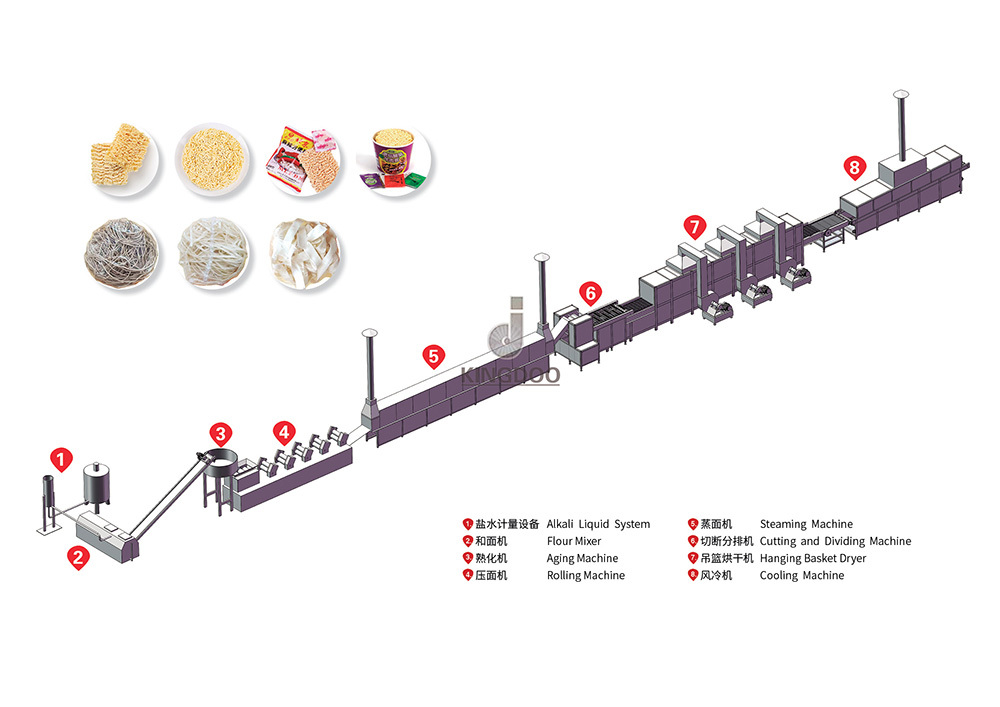

We exported this model 1000 dried noodle line in the end of march 2017 to Indonesia SUBUR JAYA COMPANY. The capacity is 350.000 pieces for 8 hours.(this model is biggest model in china at that time)

India SS food company 330 fried instant noodle line

Introduce:

We exported three sets model 330 fried instant noodle production lines to India these 2 years. The noodle machine capacity is 120,000 pieces 8 hours. noodle is square shape and 25-30gram.

About Us

Zhengzhou kingdoo machinery co., ltd is specialized in food machinery of HeNan province and built from 1991. we have over 40 skilled workers,4 professional engineers which for designing,8 installing engineers ,2 quality inspectors,4 international trading salesman.

Our team could provide processional service, good quality products, delivery in time and competitive price. We also accept OEM and ODM order. Our company has a strong research ability, manufacturing capacity and rich management experience

Built from 1991

Over 40 skilled workers

34 years of industry experience

News

Company news, industry trends updated in real time, to grasp the cutting-edge information dynamic

Jan 10,2024

Jan 10,2024